Application of screen changer in recycled plastic recovery production

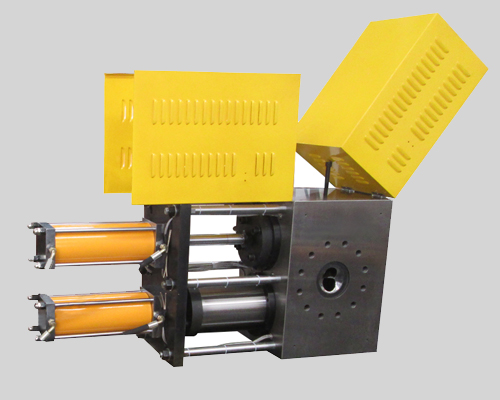

Recycled plastics are usually recycled and granulated. The recycled plastic is broken, cleaned, dehydrated and dried, and then granulated. The granulator unit generally consists of a feeder, feeding device, granulator, mesh changer, granulating die, granulator and so on. In the granulating process, it can be divided into water cut bar, grain cutting, water ring cutting, hot cutting and so on. Different granulating processes require different types of mesh changer for different production requirements. The converter is divided into single plate type double station net converter, double board and double station net converter, double post and double station net change device, net belt type fully automatic forrecycling screen changer, which are all suitable for granulation production, and can choose different network devices according to different working conditions and production requirements.

Nowadays, in the application of recycling granulation, the forrecycling screen changer is widely used, such as manual switching device, electric net exchanger and pneumatic switching device, with low cost, ordinary steel, even without heat treatment, poor sealing treatment, general leakage, and need to stop the net, but it is suitable for low end. Recovery and granulation production with low productivity.