What is the function of adding net screen changer in plastic pelletizing production line

Many plastics machinery users do not yet know that plastic machines can be replaced with mesh screen changer. If the mesh screen changer is installed, not only the impurities can be filtered out, but also the plasticizing and homogenizing effect of raw materials can be greatly improved. The product quality is more even, the surface quality and smoothness are better. In addition, the filter can be replaced in the case of non-stop, saving energy and reducing consumption, while increasing production and reducing labor intensity. Using the screen changer saves manpower. It also saves costs and improves production efficiency.

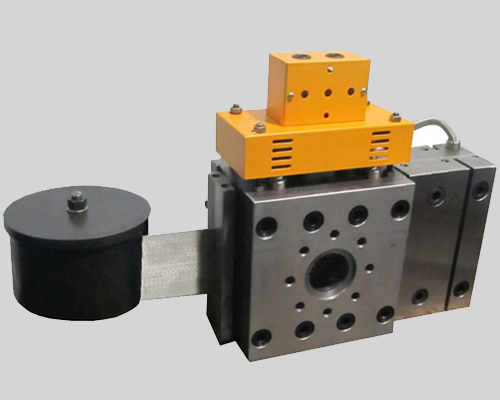

At present, the most common ones are hydraulic changer and manual screen changer. Secondly, the plunger type non-stop changer, because of the high cost of the plunger type non-stop changer, less users in China. The following is a brief introduction of the manual network changer solution.

Zhengzhou batte manual mesh changer is a low-cost filtering scheme for rubber and plastic extrusion industry. The manual mesh changer is suitable for applications where the machine can be temporarily shut down to change the mesh. Haike can design and manufacture mesh screen changers which can withstand higher pressure or be used for special materials according to customer's special needs. Manual changers can also be integrated with unloading valves. Small screw extruders are generally equipped with manual screen changers. Manual mesh screen changer occupies little space and the operator makes it.