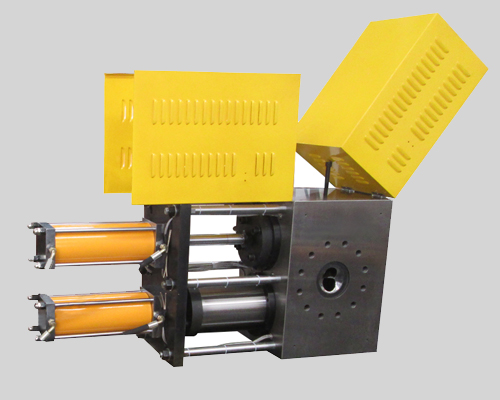

fully automatic backwash screen changer

The fully automatic backwash screen changer is composed of backwash body, backwash plunger, porous plate, filter screen, heater and program control device.

The plastic melt flows through the filter screen on the plunger, and impurities accumulate gradually in the filter screen. The melt pressure increases with the accumulation of impurities. Two melt pressure sensors are installed in the backwash screen changer to measure the pressure of the front and rear parts of the filter respectively. When the preset pressure difference is reached, the backwash is automatically carried out. The backwash plunger moves under the push of the hydraulic cylinder, changes to the backwash position, and a small part of the melt flows backward, which flushes the impurities accumulated in the filter screen back to the waste bin. When the time of the melt backwash reaches the predetermined time, the backwash plunger starts to move under the action of the hydraulic cylinder until the backwash plunger restores to its original position, thus realizing an automatic cleaning process of the filter screen. To achieve the purpose of cleaning the filter screen changer. Up and down backwash plunger alternately operates to implement backwash to ensure stable material pressure extrusion. Through backwashing filter, the filter can be used repeatedly, which greatly prolongs the interval of filter replacement, ensures the continuous production of extrusion equipment for a long time, effectively reduces the downtime, improves the output and economic benefits.