baclflush screen changer in recycling

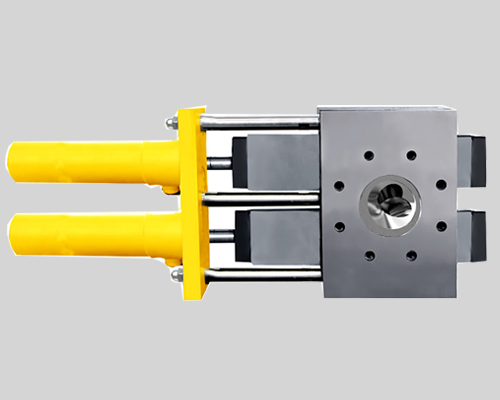

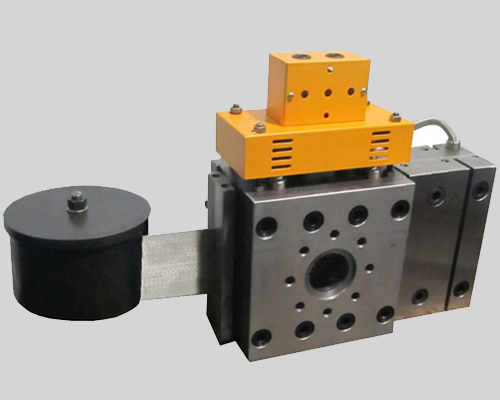

The continuous piston backflush screen changer guarantees a constant production process. As neither pressure spikes nor degraded material are created, melt purity and a constant product quality are guaranteed. Further, short flow channels – free from dead spots – guarantee a short dwell time of the melt.The continuous piston backflush screen changer is suitable for processes like compounding, film, sheet and pelletizing.

In a reprocessing line with the continuous piston backflush screen changer, ABC chiefly runs chiefly LDPE and LLDPE. Typical source material is stretch wrap, bubble wrap, and foam with up to 3% contaminants —labels, paperboard, and nylon cords or PET strands, whose higher melt temperatures result in filter-clogging “unmelts.”

In four reprocessing lines with the continuous piston backflush screen changer installed, KW Plastics runs primarily PP scrap, including rigid parts, woven and nonwoven fabrics, fibers, and film. Typical contaminants are labels, paper, cardboard, and non-PP unmelts, such as nylon and PET.