self cleaning plastics recycling screen changer

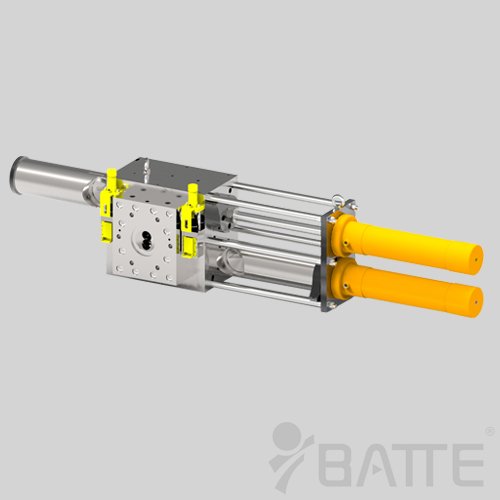

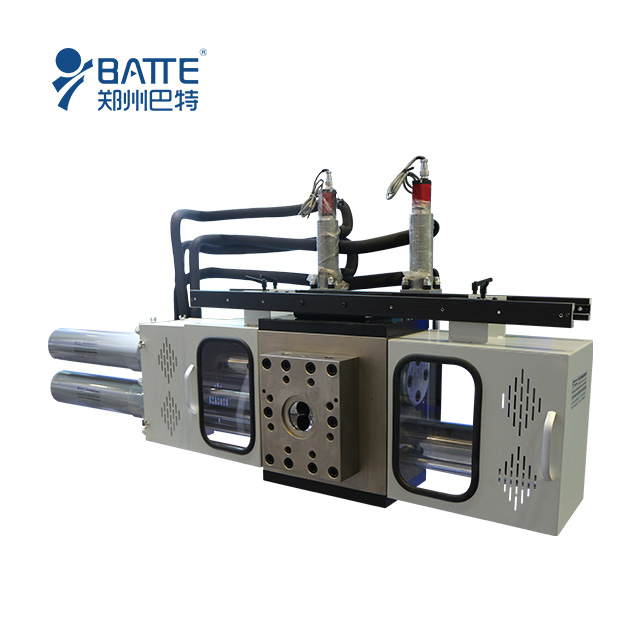

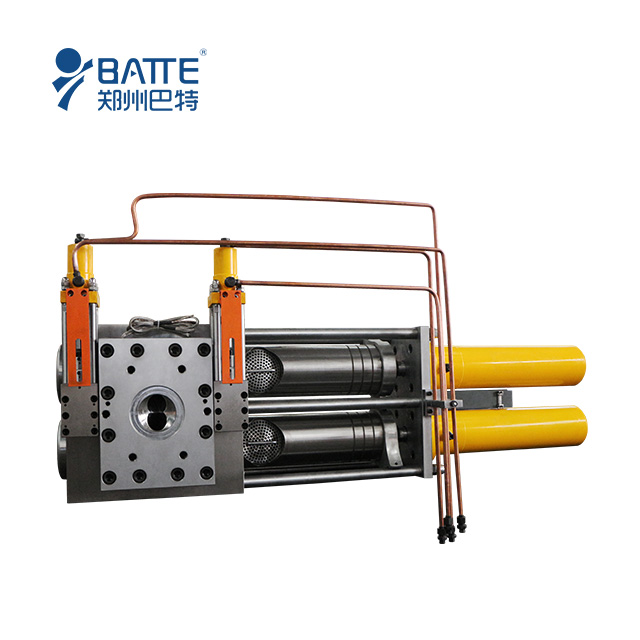

Screen changers can be installed into any new or existing extruder, melt pump, reactor or other extrusion line. It can be used to filter any type of polymer, rubber or ceramic melt. Active backwash screen changer is a kind of screen changer. Active automatic backwash screen changer generally consists of screen changer body, plunger, metal filter, porous plate, filter support, backwash body, and backwash plunger. and other components, the driving part mostly adopts hydraulic cylinder. The screen changer body and the backwash body are designed and processed separately.

Its working principle: the plastic melt flows into the screen changer body through the backwash body, the impurities are filtered out by the metal filter screen, the impurities on the filter screen gradually accumulate, and the melt pressure rises accordingly. When the melt pressure in front of the mesh reaches the set value, the backflush plunger moves downward under the advancement of the hydraulic cylinder, and a small part of the melt flows backwards. The impurities accumulated on the filter screen are taken out. When the melt backflow time reaches the preset time, the backwash plunger starts to move upward under the effect of the hydraulic cylinder, and a small part of the melt backflow will accumulate in the filter screen. The impurities are brought out, and the backflushing plunger returns to its original position after the backflow reaches the preset time. In this way, a process of actively cleaning the filter screen is completed, and the purpose of cleaning the filter screen is completed. The filter screen can be recycled to greatly extend the time between screen changes, and can be continuously produced for a long time.

In summary, the active scour upvc backflush screen changer has the following characteristics:

1. It is especially suitable for the recycling and processing of waste plastics;

2. It has the function of actively cleaning the filter screen, which can greatly reduce the frequency of changing the screen and avoid frequent squeezing and changing the screen;

3. High backwashing efficiency, avoiding production stoppage, increasing production and saving energy, and saving production costs;

4. There is no change in the material flow pressure when the screen is changed, the flow rate is stable, there is no instantaneous interruption of flow, and there is no melt leakage.

The screen changing process of the automatic flushing screen changer: when the impurities on the filter screen in the screen changer gradually accumulate, the melt pressure increases; when the melt pressure in front of the filter screen reaches the set value, the backwash column of the screen changer Pushed by the hydraulic cylinder, the plug will move downward, and a small part of the melt will flow backwards, bringing out the impurities accumulated on the filter screen; The flushing plunger starts to move upwards under the action of the hydraulic cylinder, and a small part of the melt flows back to take out the impurities accumulated in the filter screen. After the backflow reaches a preset time, the backflushing plunger returns to its original position. The automatic extruder screen changer for recycling plastic thus realizes an automatic filter cleaning process and the purpose of cleaning the filter screen. info@battemachinery.com